Ceramics have been integral to human civilizations for millennia, serving functional, decorative, and structural roles from ancient pottery to modern aerospace components. Yet the demands of today’s architecture, industry, and consumer markets push conventional ceramics beyond their traditional limits. Enter Sodiceram, a next-generation, sodium-enhanced ceramic platform that marries advanced material science with digital fabrication and sustainability to deliver unprecedented performance and aesthetic versatility. This article provides a comprehensive, standalone exploration of Sodiceram—its origins, composition, manufacturing, properties, applications, environmental credentials, market impact, design integration, and future trajectory.

Origins and Evolution

From Laboratory Curiosity to Commercial Breakthrough

In the early 2000s, a multidisciplinary team of materials scientists and ceramic artisans set out to overcome the limitations of standard alumino-silicate ceramics—namely brittleness, high firing temperatures, and restricted design flexibility. Drawing inspiration from traditional glazing practices that employed sodium compounds to lower melt points, they hypothesized that a judicious increase in sodium oxide content, combined with modern reinforcements, could produce a ceramic matrix with superior toughness and lower energy requirements.

Initial laboratory experiments in 2004 demonstrated that prototypes containing 15–18% sodium oxide exhibited up to 25% greater flexural strength and required firing temperatures 100–150 °C lower than comparable porcelains. Encouraged by these results, the consortium formed a pilot facility in 2007 to refine batch formulations, integrate micro-reinforcements such as zirconia whiskers and silicon carbide particles, and explore digital glazing methods.

By 2010, small-batch decorative tiles bearing the moniker “Sodiceram” emerged, garnering acclaim for their vivid, fade-proof surfaces and tactile finish. Strategic partnerships with distributors in Europe and North America soon followed, facilitating expansion into both residential and commercial design markets.

Scaling and Technological Milestones

Between 2012 and 2018, Sodiceram achieved several key milestones:

-

2012 – Launch of nano-engineered “Smart Glaze” pigments that resist UV fading and chemical attack.

-

2014 – Adoption of extrusion-based 3D printing for bespoke architectural and industrial components.

-

2016 – Certification under ISO 14001 for environmental management and early participation in LEED pilot programs.

-

2018 – Introduction of the “ThermaCore” high-performance line, optimized for rapid thermal cycling and demanding engineering contexts.

These innovations transformed Sodiceram from a boutique artisan brand into a leading materials technology company, able to serve sectors as diverse as luxury interior design and heavy-duty industrial processing.

Chemistry and Composition

Sodium-Enriched Matrix

The hallmark of Sodiceram lies in its sodium-enriched ceramic matrix. A typical formulation comprises:

-

Alumino-silicate clay (40–50%): Imparts plasticity and sintered strength.

-

Sodium oxide (Na₂O) (12–18%): Lowers the glass transition and sintering temperatures, enhancing densification and fracture toughness.

-

Feldspar and quartz (20–30%): Provide glass-forming phases and control thermal expansion.

-

Zirconia (ZrO₂) (3–6%): Undergoes transformation toughening, arresting crack propagation.

-

Silicon carbide (SiC) (1–3%): Adds wear resistance and thermal conductivity where needed.

-

Nano-pigments (< 1%): Enable rich, UV-stable coloration in digital glazes.

Adjusting the Na₂O content and reinforcement ratios allows developers to tailor mechanical, thermal, and visual properties precisely for targeted applications.

Reinforcement Mechanisms

-

Transformation Toughening: Zirconia particles within the matrix transform phase under stress, generating compressive forces that inhibit crack growth.

-

Intergranular Bonding: Sodium flux promotes the formation of a continuous glassy phase, reducing porosity and increasing mechanical cohesion.

-

Particle Bridging: SiC and other hard phases bridge microcracks, improving wear resistance and hardness.

Collectively, these mechanisms yield flexural strengths up to 300 MPa and fracture toughness values exceeding 4 MPa·m¹ᐟ²—metrics that dwarf traditional porcelains and rival advanced technical ceramics.

Manufacturing Processes

Sodiceram’s production marries established ceramic workflows with cutting-edge digital and additive techniques, all underpinned by rigorous quality control and environmental stewardship.

Raw Material Preparation

-

Sourcing: High-purity clays, feldspars, and silica are procured from certified, responsibly managed quarries. Post-industrial ceramic waste is reclaimed and milled for up to 15% recycled content.

-

Blending: Precision weighing and dry mixing ensure consistent batch composition before the addition of deionized water and dispersants to create a homogenous slurry.

Forming Techniques

-

Slip Casting: Fluid slurries cast into plaster molds produce complex shapes—vases, relief panels, and ornamental elements—with fine detail and uniform density.

-

Pressing & Extrusion: For standard tiles and structural blocks, hydraulic pressing or extrusion yields flat panels, bricks, or profiled sections with tight dimensional tolerances.

-

3D Ceramic Printing: Binder-jet and paste extrusion printers enable bespoke geometries, internal lattices for lightweight panels, and integrated conduits for fluid or electrical paths.

Digital Glazing & Decoration

-

Nano-Pigment Slurries: Ultra-fine pigment suspensions are digitally deposited via robotic nozzles under CAD control, achieving resolution down to 50 microns.

-

Layered Colors: Multi-pass printing allows gradient effects, photorealistic imagery, and tactile textures in a single firing cycle.

-

Pre-Firing Stabilization: UV or mild heat curing locks pigments in place to prevent migration during high-temperature firing.

Firing and Thermal Treatment

-

Fast-Ramp Kilns: Advanced electric–gas hybrid kilns ramp at up to 10 °C/min, shaving hours off traditional cycles while preserving microstructure integrity.

-

Peak Temperatures: Typically between 1,150 °C and 1,300 °C, optimized per batch to balance densification and grain growth.

-

Controlled Cooling: Programmable cool-down profiles ensure proper zirconia phase distribution for maximum toughness.

Quality Control

-

Dimensional Scanning: Laser profilometers verify panel flatness (< 0.1 mm across 1 m²) and edge precision.

-

Ultrasonic Testing: Detects subsurface voids or delamination with micron-scale sensitivity.

-

Surface Characterization: Gloss meters, spectrophotometers, and hardness testers confirm that color, sheen, and mechanical properties meet stringent specifications.

Material Properties

Sodiceram’s engineered chemistry unlocks a suite of high-performance properties:

Mechanical Performance

-

Flexural Strength: 200–350 MPa, depending on grade—double that of standard porcelain.

-

Fracture Toughness: 4–6 MPa·m¹ᐟ², thanks to transformation toughening.

-

Vickers Hardness: 1,000–1,300 HV, offering outstanding scratch and abrasion resistance.

Such metrics make Sodiceram suitable for both decorative and structural roles.

Thermal Characteristics

-

Coefficient of Thermal Expansion (CTE): 6–8 × 10⁻⁶ K⁻¹, closely matching many metals and composites to minimize thermal stress.

-

Thermal Conductivity: 2–4 W/m·K, balanced for insulation or moderate heat dissipation depending on reinforcement content.

-

Thermal Shock Resistance: Survives ΔT of 200–300 °C without cracking, enabling use in rapid-cycling environments.

Chemical and Environmental Stability

-

Acid/Alkali Resistance: Stable in pH 2–12, ideal for laboratory countertops and chemical plant linings.

-

UV and Fade Resistance: Nano-pigment glazes maintain color fidelity for decades under direct sunlight.

-

Water Absorption: < 0.05%, ensuring frost resistance and durability in exterior applications.

Aesthetic Versatility

-

Surface Finishes: Options range from ultra-matte to high-gloss, with micro-textured or tactile patterns.

-

Color Gamut: Full RGB spectrum, including metallic and pearlescent effects.

-

Texture and Relief: Molded surface patterns and reliefs add depth and shadow play for dramatic visual impact.

Product Portfolio

Sodiceram’s diverse range serves architects, designers, engineers, and consumers:

Decorative Tiles and Panels

-

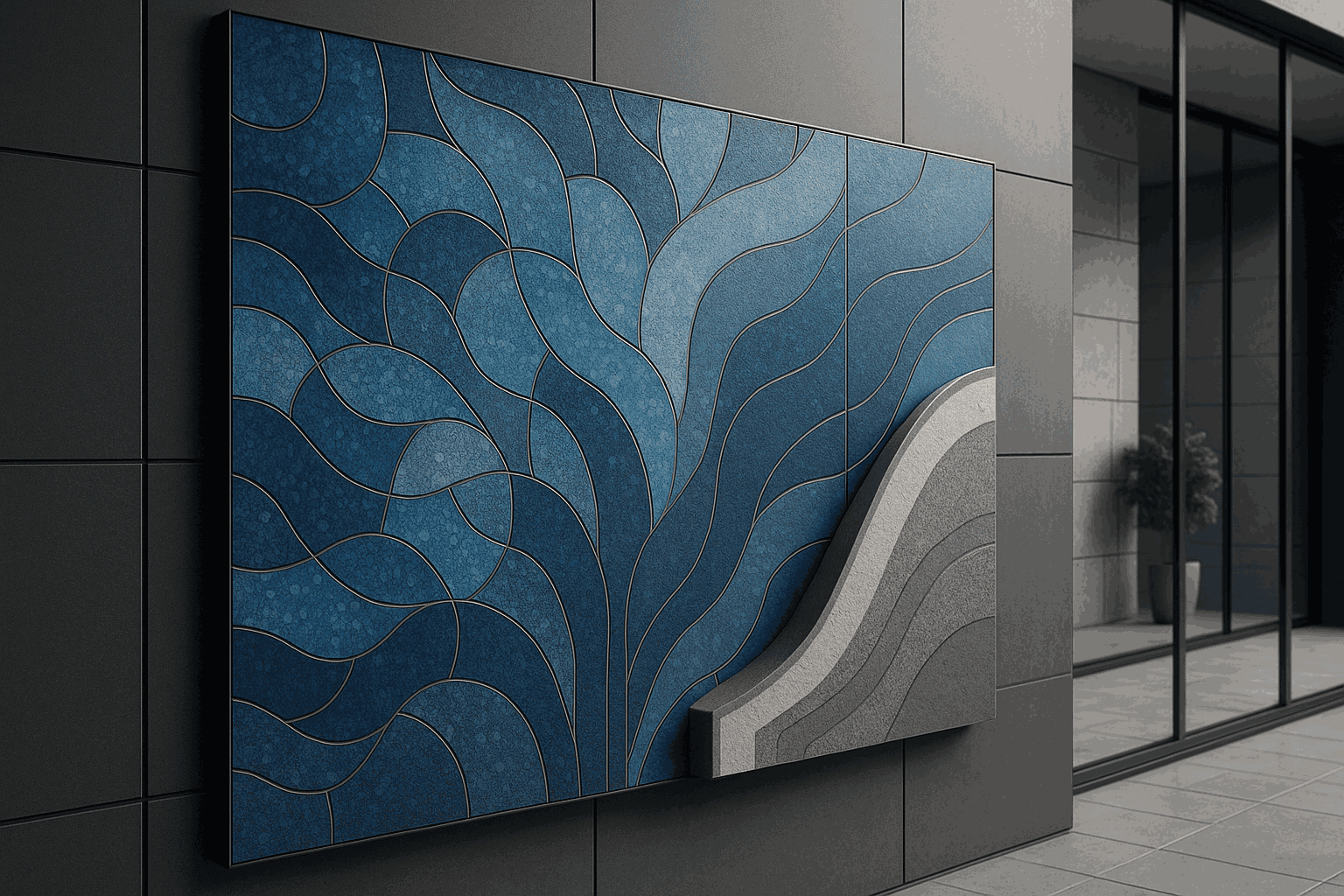

Feature Walls: Large-format panels up to 1 × 3 m, thicknesses from 3 mm to 12 mm, ideal for open-plan spaces or lobbies.

-

Mosaics: Micro-tile modules with intricate digital patterns, supporting both rectilinear and curvilinear installations.

-

Accent Tiles: Smaller units with high-definition photographic prints or metallic inlays for custom backsplash and furniture insets.

Flooring Solutions

-

Residential: Polished or textured planks and slabs compatible with underfloor heating.

-

Commercial: Slip-resistant, chemical-resistant grades for retail, hospitality, and light industrial environments.

-

Modular Flooring Systems: Interlocking panels with integrated under-panel diffusion layers for rapid installation and acoustical dampening.

Architectural Façades

-

Rainscreen Cladding: Ventilated rainscreen panels with concealed mechanical anchors, supporting wind loads up to 2 kPa.

-

Curtain Wall Infill: Thin-section ceramic glazing with reinforced cores for minimal dead load on supporting structures.

-

Custom Geometries: 3D-printed façade elements offering biomorphic forms, parametric facades, and integrated shading devices.

Industrial Linings and Components

-

Kiln and Furnace Linings: High thermal shock tolerance reduces maintenance cycles in steel, glass, and petrochemical plants.

-

Wear Parts: SiC-reinforced sleeves, nozzles, and chutes for mining, cement, and bulk handling.

-

Heat Exchanger Cores: Ceramic core exchangers in solar thermal applications, offering corrosion resistance and high temperature stability.

Consumer and Lifestyle Products

-

Cookware: Pans, baking dishes, and griddles with non-stick ceramic surfaces that combine scratch resistance with even heat distribution.

-

Tableware: Vibrant, oven-to-table plates and serving ware featuring fade-proof nano-glaze images.

-

Lighting: Thin, translucent pendant and wall fixtures that diffuse LED light softly through ceramic substrates.

Smart Ceramics

-

Sensor-Embedded Tiles: Prototype panels with integrated temperature and moisture sensors for building health monitoring.

-

Reactive Surfaces: Photo-chromic and thermo-chromic glazes under development to create façades that dynamically shift color with environmental conditions.

Sustainability and Environmental Responsibility

Environmental stewardship is woven into every stage of Sodiceram’s lifecycle:

Circular Raw Materials

-

Recycled Content: Up to 20% of batch weight from post-industrial ceramic waste—broken tiles, rejects, and factory sludge.

-

Local Sourcing: Clay, feldspar, and silica sourced regionally to reduce transportation emissions.

Water and Energy Efficiency

-

Closed-Loop Water: Slip casting and glaze lines recycle over 95% of process water via sedimentation and filtration.

-

Heat Recovery: Kiln exhaust heat is captured to preheat incoming combustion air, cutting overall energy use by 10–15%.

-

Fast-Cycle Kilns: Reduced ramp times and hybrid gas-electric operation lower CO₂ emissions by up to 20% compared to conventional tunnel kilns.

Certifications and Reporting

-

ISO 14001: Certified environmental management systems.

-

Life Cycle Assessments (LCA): Full cradle-to-gate LCA studies enable architects to claim LEED and BREEAM credits.

-

Annual Sustainability Reports: Transparent disclosure of energy use, water balance, material sourcing, and waste metrics.

Through these measures, Sodiceram not only reduces its ecological footprint but also empowers clients to meet their own green building targets.

Applications and Case Studies

Luxury Hospitality Interior

At the Aurora Grand Hotel, a 200 m² lobby feature wall was clad in custom “Aurora Sands” panels—6 mm-thick ceramic sheets with gradient copper and gold nano-glazes. The panels’ lightweight design and hidden stainless steel anchors allowed rapid installation over existing plasterboard, while the glazes’ UV stability ensured no color drift under lobby lighting.

Urban Transit Station

Berlin’s Eastside Metro station employed 5,000 square feet of high-traffic platform tiling in a slip-resistant, acid-etched finish. After two years of continuous service and daily ridership exceeding 100,000 passengers, no individual tile has chipped, cracked, or shown significant wear.

Industrial Kiln Modernization

A Midwest steel mill retrofitted its aging refractory brick linings with “ThermaCore” Sodiceram modules. Downtime for re-lining was reduced by 15%, and thermal cycling tests revealed that the new modules outlasted traditional bricks by an estimated 30%.

Solar Thermal Power Plant

In southern Spain, a pilot concentrated solar power (CSP) facility integrated ceramic recuperator cores to preheat combustion air. The ceramic’s corrosion resistance to salts and high-temperature stability under cyclic loading improved net plant efficiency by 4%—a significant gain in large-scale solar operations.

Public Art Façade

For a cultural center in Tokyo, an artist collaborated with Sodiceram engineers to produce a 300 m² ceramic mural depicting cherry blossoms in relief. Each tile varied in thickness from 4 mm to 15 mm, creating a dynamic play of light and shadow. The project won awards for innovation in public art integration.

Market Impact and Industry Trends

Disrupting Traditional Ceramics

By demonstrating the commercial viability of sodium-rich formulations and digital glazing, Sodiceram has influenced competitors to explore higher flux contents and adopt CAD-driven decoration. Today, digital printing lines and additive manufacturing are standard in many leading ceramic factories—a testament to Sodiceram’s pioneering efforts.

Expanding End-Use Segments

Initially focused on design tiles, Sodiceram has rapidly penetrated heavy industry, energy, and aerospace. Its balanced cost-to-performance profile makes it an attractive alternative to both low-end mass-market ceramics and prohibitively expensive technical ceramics, opening new market niches.

Driving Smart Materials Adoption

The company’s forays into sensor-embedded tiles and reactive glazes have positioned Sodiceram at the vanguard of “smart materials.” Industry watchers predict a wave of built-environment products incorporating real-time monitoring, adaptive aesthetics, and integrated controls—areas where ceramics have rarely ventured until now.

Design Integration and Best Practices

Collaborating with Architects and Designers

-

Early Engagement: Involve Sodiceram specialists during concept design to align performance requirements (load-bearing, thermal, chemical) with desired aesthetics.

-

Digital Mock-Ups: Use 3D-printed prototypes and online pattern configurators to preview large-scale installations before production.

-

Material Selection: Choose from decorative, structural, or high-performance grades based on project demands.

Installation Guidelines

-

Substrate Preparation: Ensure flatness within ± 2 mm over 1 m² to avoid stress concentrations.

-

Adhesion Systems: Utilize polymer-modified thin-set mortars for wall panels; epoxy or cementitious adhesives for flooring.

-

Joint Specifications: Maintain expansion joints every 3–5 m on façades; flexible sealants accommodate thermal movement.

-

Anchorage Methods: For façade panels larger than 1 m², employ concealed stainless steel clip systems to manage wind loads.

-

Maintenance: Clean surfaces with pH-neutral cleaners; abrasive pads optional for textured finishes.

Following these protocols ensures long-term stability, performance, and visual integrity.

Future Directions and Research

Sodiceram continues to invest heavily in R&D, with active programs in:

-

Bio-inspired Self-Healing Ceramics: Mimicking nacre’s “brick-and-mortar” microstructure to enable micro-crack repair through embedded healing agents.

-

Low-Carbon Binders: Developing bio-based dispersants and binders derived from agricultural waste, further reducing lifecycle carbon emissions.

-

Thermo-chromic and Photo-chromic Glazes: Crafting reactive surfaces that shift color in response to temperature or light, allowing interactive façades and environmental feedback.

-

Integration with Building Automation: Scaling sensor-embedded tile systems that feed real-time data into smart-building networks for predictive maintenance and energy optimization.

By 2030, Sodiceram aims to have commercially viable self-healing tiles, fully bio-sourced ceramic binders, and a global network of sensor-integrated installations in major smart cities.

TheSpoonAthletic Fitness Tips: Your Complete Guide to Smarter Training, Nutrition & Performance

Conclusion

Sodiceram stands at the intersection of tradition and innovation—reimagining a time-honored material through the lens of advanced chemistry, digital manufacturing, and sustainability. Its sodium-enriched matrix, reinforced with state-of-the-art reinforcements, delivers mechanical and thermal performance once thought exclusive to specialty technical ceramics. Coupled with high-definition digital glazing, 3D printing, and a commitment to environmental stewardship, Sodiceram offers architects, designers, and engineers a truly versatile material platform. From luxury hotel lobbies and public art murals to industrial furnaces and solar power plants, Sodiceram is reshaping expectations of what ceramics can achieve. As it pursues smart-material integration, self-healing composites, and bio-based innovations, Sodiceram is poised to lead the ceramics industry into a future defined by performance, beauty, and responsibility.